DISCUSSION: Cornering Stiffness

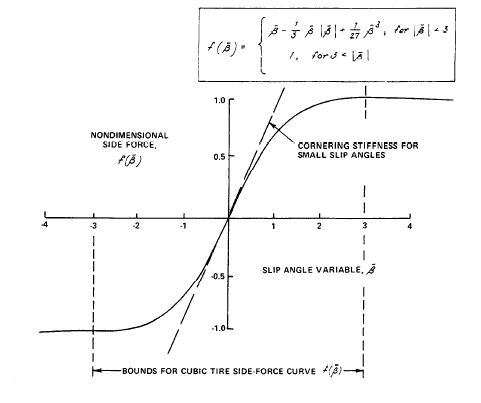

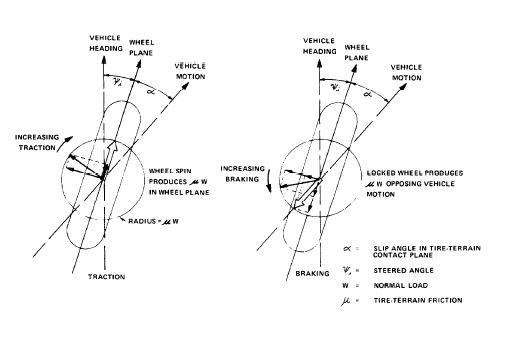

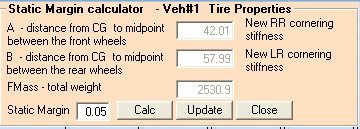

When a tire is orientated at an angle not equal to its direction of motion, a side force acts perpendicular to the plane of the wheel. The relation is nearly linear for small slip angles. The relationship that defines side force as a function of slip angle makes use of the tire cornering stiffness. The SMAC program calculates tire side forces based on a nondimensional side force function whereby the small-angle properties of the tires become progressively "saturated" at larger angles (Figure 6). The "friction circle" concept (Figure 7) is used to approximate interaction between side and circumferential (braking and tractive) tire forces. This concept is based on the assumption that the maximum value of the resultant tire friction force is independent of its direction relative to the wheel plane. The general approach to the modeling of tire properties is patterned after that of Reference 12. The cornering stiffnesses of the individual wheels are input separately in the SMAC program.

Figure 5 Automobile Tire Cornering Stiffness from Reference 27

Figure 6 Tire cornering stiffness

Figure 7 Friction Circle

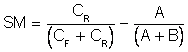

For most automobiles, the relationship between the distribution of tire cornering stiffnesses and the vehicle weight distribution is designed to produce understeer. A simple means of approximating the general properties of a vehicle in a cornering maneuver is to calculate the vehicle Static Margin (SM). The vehicle static margin is defined by the relationship between the front and rear cornering stiffnesses and the weight distribution of the vehicle.

The static margin (SM) may be defined as

where CF, CR = cornering stiffnesses per tire at front and rear respectively, LB/RAD.

A, B = longitudinal distances from the complete-vehicle center of gravity to the front and rear wheel centers, respectively, INCHES.

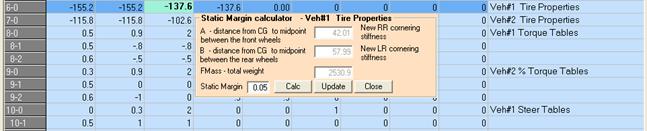

Figure 8 Input Card 6 or 7 produces popup Static margin dialog

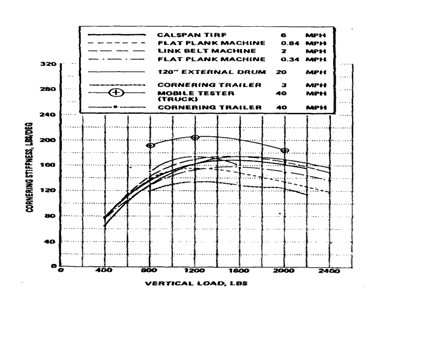

A close up of the pop is as follows:

Figure 9 Closeup of the Static Margin Calculator

The Static Margin is calculated as follows:

SM = -5158/(-7123-5158) - 37.83/(37.83+59.17) = 0.03

You can also use the Static Margin dialog box to determine:

• the tire cornering stiffness properties required to change the Static Margin to a specified value

• the Static Margin which would result in a change to the Cornering Stiffness.

WRF = WLF = (W/2) *B/(A+B) LBS.

CRF = CLF = -9.455 * W1 LB/RAD

CRR = CLR = CRF * (TEMP1/TEMP2)

CRF = CLF = -.165 * WRF LB/DEG

CRR = CLR = CRF * (TEMP1/TEMP2)

CRR = CLR = CRF * (TEMP1/TEMP2)

Note: the sign of the value for the cornering stiffness is ignored in the m-smac program.

Further Reading

Further Reading