TRUCK/TRAILER TIRE PROPERTIES

When a tire is orientated at an angle not equal to its direction of motion, a side force acts perpendicular to the plane of the wheel. The relation is nearly linear for small slip angles. The relationship that defines side force as a function of slip angle makes use of the tire cornering stiffness.

The SMAC program calculates tire side forces based on a nondimensional side force function whereby the small-angle properties of the tires become progressively "saturated" at larger angles (Figure 6). The "friction circle" concept (Figure 7) is used to approximate interaction between side and circumferential (braking and tractive) tire forces. This concept is based on the assumption that the maximum value of the resultant tire friction force is independent of its direction relative to the wheel plane. The general approach to the modeling of tire properties is patterned after that of Reference 12. The cornering stiffnesses of the individual wheels are input separately in the SMAC program.

(Please note the following: The track width and wheelbase used for dual and/or tandem axles should be the location of the center of the dual/tandem combination. Also note that although the use of an equivalent cornering stiffness to model dual/tandem tires is adequate and sufficient, modifications are currently being implemented to permit specifying dual/tandem distances and individual tire properties to allow comparison and testing of the use of the equivalent tire model. These modifications should be implemented by 3rd quarter 1998).

Typical values for the cornering stiffness in lbs. per degree of slip angle for automobile tires are generally in the range of 16-17% of the load on the tire (Please see page 120 “Extended Tire Testing”, Tapia, Calspan, Nov 1983, Contract DTNH22-81-C-07100, NTIS PB 85 103604 for additional information on automobile tire properties). Measurement of the cornering stiffness for Truck tires are contained in “Effects of Tire Propertiesxe "TIRE PROPERTIES" on Truck and Bus Handling”, Ervin, R.D., Winkler, C.B., Bernard, J.E., Gupta, R.K., DOT-HS-802 141, UM-HSRI-76-11, Contract DOT-HS-4-00943, Dec 1976, Volume 1: NTIS PB 263 878, Volume II, Appendix C: NTIS PB 263 879, Volume III, Appendices D,E,F,G: NTIS PB 263 880.

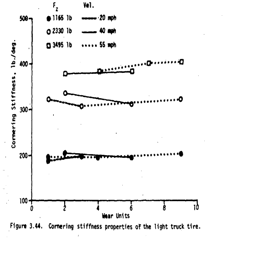

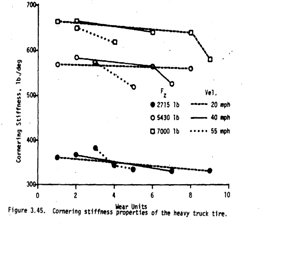

Figure 16 Cornering Stiffness Properties of Light truck tires (Left) and Heavy truck tires (Right) from Reference 23

These measurements for light and heavy truck tires are from Reference 23, and lead to the following approximations of the small angle cornering stiffness for light and heavy truck tires:

Light Truck Tires @3495 lbs. CSTF approx. 11% of load

@2330 lbs. CSTF approx. 14 % of load

@1665 lbs. CSTF approx. 17 % of load

Heavy Truck Tires @7000 lbs. CSTF approx. 8-10% of load

@5430 lbs. CSTF approx. 10 % of load

@2715 lbs. CSTF approx. 13 % of load

The input values for the small angle cornering stiffness used and published in References 19 – 24 indicate a range of values used for CSTF from 600 – 722 lbs./degree.

DISCUSSION: Bus Properties

DISCUSSION: Bus Properties